Longi?s Hi-MO N module offers a 2-3% energy performance improvement over the mainstream p-type PERC.

The PV solar cell market is taking an interesting shift. While the p-type cells have been more popular throughout the history of solar energy development, things might be looking different in the future.

P-type cells enjoy many benefits. They have been dominating the market practically since the beginning of this technology.

While the first cell was an n-typemono-crystalline, p-type soon kicked in and reached the greatest market share.

In 1954, Gerald Pearson, Calvin Fuller, and Daryl Chapin developed the first silicon photovoltaic cell at Bell Labs. It was the first device capable of powering day-to-day electrical equipment using solar energy.

Soon, solar cells started to gain popularity, but they were mainly used for space projects. In this context, p-type showed better resistance to radiation which was one of the main reasons for its success.

In the past four decades, p-type cells dominated the solar energy landscape and they still do so nowadays. This technology is cost-effective and enjoys the benefits of economy of scale. However, this may change in the not-so-distant future.

P-type panels show better resistance to radiation

The advantages of n-type technology are no secret for the big market players, who are striving to get ahead of the game. Many of the industry giants are performing extensive research and creating n-type prototypes and tests. Although still not ready for massive production, there have been some encouraging advancements in this field.

In June 2021, Longi, the largest PV manufacturing company, has released an innovative n-type-based product that is highly promising. Is this the beginning of a new era for the PV cell industry?

Difference between p-type and n-type solar cells

The p-type cell is based on a positively charged silicon base (hence its name ?p-type?) The wafer is doped in boron which is one electron shorter than silicium. To create a flow of electricity, the upper part of the wafer is negatively doped with phosphorous (one electron less than silicium).

N-type cells work inversely. In this case, the negatively charged pole serves as the cell?s basis.

While these are mainly structural differences, these technologies also differ in other aspects. They both present advantages and disadvantages. This arises the following question. If p-type has been the leader for almost half a century, then why is there a clear tendency towards n-type research and development?

How can n-type compensate p-type?s deficiencies?

Efficiency

The p-type technology has a deficiency called the ?boron-oxygen defect?. When ingots grow, they usually have a high concentration of dissolved oxygen coming from the quartz where the silicon was melted. Thus, the oxygen creates a recombination area that causes the system to be less efficient.

The ?boron-oxygen defect? causes a cell to lose efficiency over time.

N-type technology, on the other hand, uses phosphorous, hence it doesn?t suffer from this defect. These are also less prone to metallic impurities of the silicon.

Light-Induced Degradation effect (LID)

P-type presents a light-induced degradation effect (LID), also caused by the ?boron-oxygen defect?. This causes the module?s performance to decrease.

Cost

So far, this is the only aspect in which p-type is more advantageous. Although the building costs for p-type and n-type do not differ much, the balance is inclined towards the former.

N-type ingots are more expensive to manufacture. Also, the fabrication process for n-type modules is longer and requires more steps. This makes them more expensive and complicated to build.

N-type cells are more efficient but more expensive to build

Today?s trends in solar cell technology

A few years ago, manufacturers did not put much thought into the underlying technology behind solar cells. Things were going well as long as the capacity increased and efficiency improved. However, there came a time when Al-BSF technology began to show its limitations.

For over 30 years, the market growth has been sustained by PERC modules. The argument was that this technology was cheaper. Nowadays, while PERC products are still developing and increasing capacity, there is a clear tendency towards n-type.

With supplies and shipping costs increasing, particularly since March 2020, it has become necessary for manufacturers to compete for a better market position. It is vital to optimize efficiency and costs so that these companies can provide a competitive product.

The market is taking mainly two different routes. While p-type mono and multi PERC are still being developed, many players are increasing n-type wafer capacity.

In many cases, their trials are successful and the ITRPV predicts a major market share for this new tendency. It seems the market may be more balanced in the years to come.

N-type solar development

Experts estimate that by the end of this year, there will be approximately 400 GW of mono PERC cell capacity. This is twice the capacity we found in 2020. With this surplus, Tier 1- cell manufacturers could see their profits reduced in the first quarter.

Higher costs, lower demand

Manufacturers continue to target the same markets. Chinese companies keep targeting mainly utility-scale projects with n-type TOPCon cells. However, despite its efficiency advantages, n-type cells have not surpassed p-type technology. P-type PERC-based modules have reached beyond 500 W.

The cost increase of raw materials such as silver lowers the demand for n-type cells. This, plus the expansion of the economy of scale for p-PERC cells makes it difficult for n-type technology to remain competitive in 2021. This has made the n-type cell production decline to 60 W, while the market share was reduced from 5% in 2020 to 4 % in 2021.

Other manufacturers are keeping their focus on their usual niches: C&I rooftop projects and residencies. Like their Chinese counterparts, many companies are developing strategies for further capacity development. Maxeon, for example, is betting on PERC technology and announced plans to expand capacity.

Everything seems to indicate that the market won?t bring surprises regarding location. Besides China, the strongest PV cell producers will be Japan, Europe, and the US.

N-type capacity

However, the PERC expansion has its downside. The market surplus for this technology is threatening to reduce profitability. With capacity considerably higher than production, many manufacturers may choose not to keep adding PERC capacity. Most projects for the second half of the year are focused on technology research and n-type products.

Moreover, major PV panel manufacturers are taking their research towards n-type cells. If these expansion plans succeed, this may result in a profitability increase and larger demand. Companies like Longi (with their TOPCon projects) or Tongwei (with their 1 GW HJT expansion project) may very well help n-type technology to reach economy of scale.

Although this is unlikely to happen in 2021, it certainly indicates a path to what may be a significant change in the future market share.

When comparing TOPCon with HJT, the former seems to be throwing better results. The equipment Capex for TOPCon decreased last year, which made the building costs much closer to PERC modules. This, plus the superior efficiency has caused PERC producers to upgrade to TOPCon.

If manufacturers manage to stabilize the efficiency/profitability ratio, TOPCon may surpass HJT both in production and capacity. From a technical point of view, builders need yet to solve the issue involving the wraparound polysilicon layer.

For now, the HJT building process is relying on silver and presents good levels of efficiency and profitability. The advent of Chinese equipment suppliers for HJT cells offering lower prices has helped to optimize costs.

Although many companies are putting their expansion plans on hold due to the financial depression, others still choose to be at the avant-garde of solar energy development. Tongwei and HuaSun have released expansion projects at a pilot-scale this year.

The performance of HJT cells in the overall market will depend on whether they can reduce the costs per watt in the remaining months of 2021. This reduction directly relates to the evolution of silver paste technology and the economy of scale.

While HJT?s prices remain much higher than p-PERC cells, it will be hard to develop production and capacity much further in the future.

he second half of 2021, companies are mainly focusing on technological research and n-type projects

Ongoing progress

Despite this, both TOPCon and HJT are showing steady progress. They both may be throwing excellent results in a 2-to-3-year period. For now, TOPCon has the advantage as it has a larger order volume and capacity. Also, it is easier to upgrade from PERC to TOPCon.

Nonetheless, if high-cost materials show a price decrease, HJT?s production and capacity will most likely grow in the long term.

However, there is a key aspect to the development of PV technologies. The market has been showing a clear tendency towards larger wafers. In the second half of the year, experts foresee that the 182 mm and 210 mm will become the standard measures for p-type.

In this aspect, n-type cells face a big challenge. We need to wait and see if TOPCon and HJT can overcome stability issues when using larger wafers. If manufacturers can achieve this, this will boost n-type technology into a mass-scale production, decreasing costs and improving profitability.

It seems clear that, even if there is a good chance for n-type to reach an economy of scale, there are several matters to be addressed. Producers need to find a way to make this technology profitable, stable, and efficient.

Longi presents its new TOPCon bifacial module

2021 brought good news for the n-type enthusiasts. Arguably the largest module manufacturer presented a new module called Hi-MO N during this year?s International Photovoltaic Electricity Generation and Smart Energy Conference & Exhibition. This is the first bifacial module with n-type TOPCon cells.

This product is available in six versions and its power ranges from 545 W to 570 W. With a 32.3 KG weight, the Hi-Mo N presents an efficiency rate between 21.3% and 22.3%. It can be operated under temperatures ranging from minus 40 to 85 degrees Celsius. Its temperature coefficient is -0.31% per degree Celsius.

This is a promising product with an optimal size (182mm cell and 72-cell), with an IP68 enclosure rating, a 2mm coated tempered glass, and an anodized aluminum alloy frame.

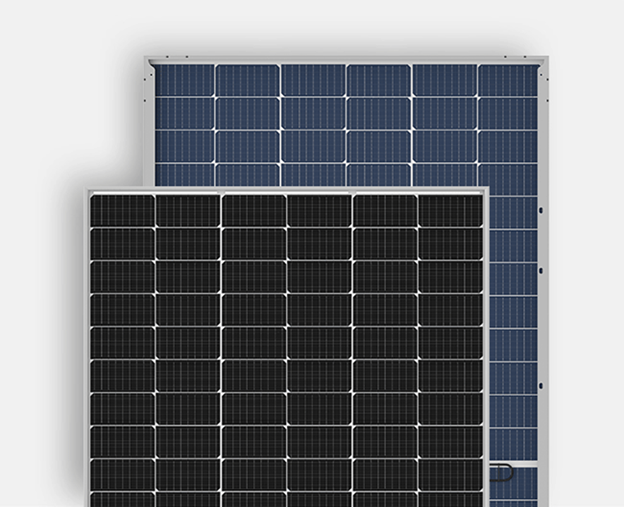

Longi?s Hi-MO 4 bifacial modules series

Longi?s new product is supposed to provide excellent efficiency in the long term. Power output is guaranteed to be at least 87.40% of the nominal power after 30 years. Also, Longi promises a degradation of less than 1% during the first year.

This company has boosted the industry?s technological development for quite some time and is responsible for many breakthroughs. Thanks to its innovative projects it managed to span p-type bifacial technology to M6 and M10 wafer standards.

Longi is committed to maximize the value of the solar cell industry and reduce LCOE. The new Hi-Mo N represents an important step in this direction offering unparalleled improved performance.

When building this technology, the company had a client-focused approach and thus made three different versions that can adapt to the customer?s needs. The Hi-MO N family includes the following products:

- Hi-MO N: This is the best option for areas with high temperatures, excessive labor costs, and limited land. It is also most suitable for surfaces with high reflection.

- Hi-MO 4: This module is to be used in mountainous regions and areas where handling this equipment can be difficult.

- Hi-MO 5: This version is most suited for ultra-large power plants.

The Hi-MO N was presented at the 15th International Photovoltaic Electricity Generation and Smart Energy Conference & Exhibition in Shanghai, China

Final thoughts on the future of N-type technology

N-type cells bring higher efficiency than their p-type PERC counterparts. Among other things, they avoid the ?boron-oxygen defect? and have fewer LID issues.

Both TOPCon and HJT technologies are striving to win the race and achieve a larger market share. However, there are yet issues to resolve.

For these technologies to reach economy of scale, manufacturers need to find a way to reduce costs and increase stability, especially in cells with larger wafers.

Nonetheless, Longi?s breakthrough this year seems to be leaning the scale toward n-type TOPCon solar cells.

The Hi-MO N brings unprecedented levels of efficiency and comes in three different versions that adapt well in different settings. Also, it offers an improvement in energy yield of 2-3% over the p-type mainstream bifacial modules.

With its low irradiance, better temperature coefficient (-0.31%), and superior PID and LID performance, the Hi-MO N can very well boost the TOPCon n-type cell technology into a more competitive market position.

Sources

Waaree, 2018, https://www.waaree.com/blog/n-p-type-cell

U.S. Department of Energy, ?The history of solar? , https://www1.eere.energy.gov/solar/pdfs/solar_timeline.pdf

Aleo Solar, https://www.aleo-solar.com/difference-n-type-p-type-solar-cells/

Amy Fang, June 17, 2021, https://www.pv-magazine.com/2021/06/17/n-type-solar-development/

Emiliano Bellini, June 4, 2021, https://www.pv-magazine.com/2021/06/04/longi-unveils-n-type-topcon-bifacial-module-with-22-3-efficiency/